Manual

Certificate

Video

- 027-81314188

- 2364840384

Transformer oil chromatograph uses chromatographic method to determine the content of dissolved gases in transformer oil. It is effective for power generation and power supply companies to determine whether there are latent overheating, discharge and other faults in oil-filled power equipment in operation to ensure safe and effective operation of the power grid. means. It is also a necessary means for manufacturers of oil-filled electrical equipment to carry out factory inspection of their equipment.

It is suitable for the determination of the content of the dissolved gas components in the insulating oil of the power system. It can complete the full analysis of the content of the 7 gas components dissolved in the insulating oil with one sample injection. The detection concentration of acetylene is up to 0.05ppm, and the stabilization time is less than 40 the minute baseline is stable.

Detection object composition: H2, CO, CO2, CH4, C2H4, C2H6, C2H2

The control panel adopts a 7-inch color touch screen design, with intuitive display, rich content and easy operation.

The self-developed electronic gas circuit control system has higher and more precise control accuracy. It has multiple control modes such as constant current, constant pressure, program pressure and flow, which realizes the comprehensive digitization and intelligence of the instrument and ensures the repeatability of analysis results. Sex and accuracy.

Using the chromatographic process with three detector signals output at the same time, the separation effect is good and the sensitivity is high.

Intelligent self-diagnosis function, the program can diagnose and protect the circuit itself. When the carrier gas leaks or loses gas, the bridge current will be automatically disconnected, which improves the reliability of the instrument

The instrument has intelligent operating procedures such as power-on self-check, automatic temperature rise, FID ignition and TCD plus bridge flow. After power-on, it can quickly reach a stable state for sample analysis without any operation.

It can remotely operate the instrument, observe spectra, query data, and remotely calibrate through the network. Multiple hosts can form a network system to realize resource sharing. Use powerful software data model and remote expert consultation to give diagnosis opinions.

|

Serial number |

Name |

Performance description |

Quantity |

|

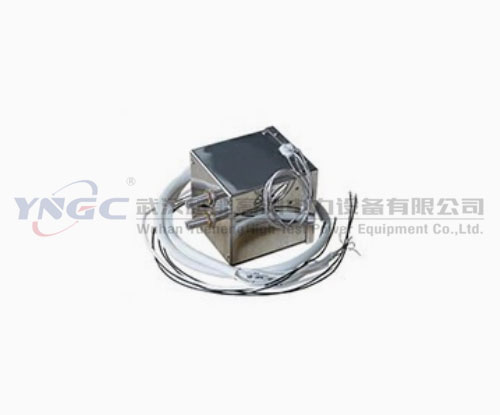

Transformer oil chromatograph |

|||

|

1 |

Host |

7-inch color touch screen display, Chinese and English switching, intelligent man-machine dialogue |

1 set |

|

Temperature control: 4℃~450℃ above room temperature, liquid nitrogen refrigeration: -80℃-400℃ |

|||

|

Column box temperature control accuracy: ±0.02℃ |

|||

|

Display accuracy: 0.1℃ |

|||

|

Oven lift rate: 21 steps and 21 platform program temperature rise, up to 120℃/min |

|||

|

Program heating repeatability: ≤1% |

|||

|

2 |

Hydrogen flame detector (FID) |

Use temperature 400℃ |

2 sets |

|

Detection limit: 5×10-12g/s (n-hexadecane) |

|||

|

Baseline drift: ≤1×10-13A/30 min (after the instrument is stable for 2 hours) |

|||

|

Baseline noise: ≤2×10-14A |

|||

|

Dynamic linear range: 107 |

|||

|

Thermal conductivity cell detector (TCD) |

Use temperature 300℃ |

1 set |

|

|

Sensitivity: S value ≥8000mv.ml/mg (benzene) |

|||

|

Baseline drift: ≤50uv/30min |

|||

|

Baseline noise: ≤10uv |

|||

|

Dynamic range: 105 |

|||

|

3 |

Column |

Transformer oil, one for measuring H2, CO, CO2, one for measuring CH4, C2H4, C2H6, C2H2, and one for TCD reference column |

3 pieces |

|

4 |

Ni conversion furnace |

Convert trace amount of CO CO2 to CH4 and respond in FID |

1 set |

|

5 |

Tools and consumables |

GC 2030 |

1 batch |

Whole machine

Whole machine Thermal conductivity cell detector

Thermal conductivity cell detector-

Nickel conversion furnace

Nickel conversion furnace -

Generator

Generator

Our company's products are produced in strict accordance with international standards, national standards, and industry and enterprise standards. They have passed professional inspections by national, provincial and municipal electric power research institutes, measurement centers and electric power authorities, and fully passed the ISO9001 international quality management system certification. GB/T19001-2008 quality management system requirements, GB/T24001-2004 environmental management system requirements, GB/T28001-2011 occupational health and safety management system requirements.

-

Pre-sale commitmentWarmly welcome calls and visits

Provide fast and professional response

Timely, serious and reasonable quotation -

Commitment in saleStrictly execute the contract

Professional technical training

Timely and regular return visits -

After-sales servicePunctual delivery with quality and quantity

Take information feedback seriously

Free lifetime technical consultation

简体中文

简体中文 English

English

Enter the mobile station

Enter the mobile station